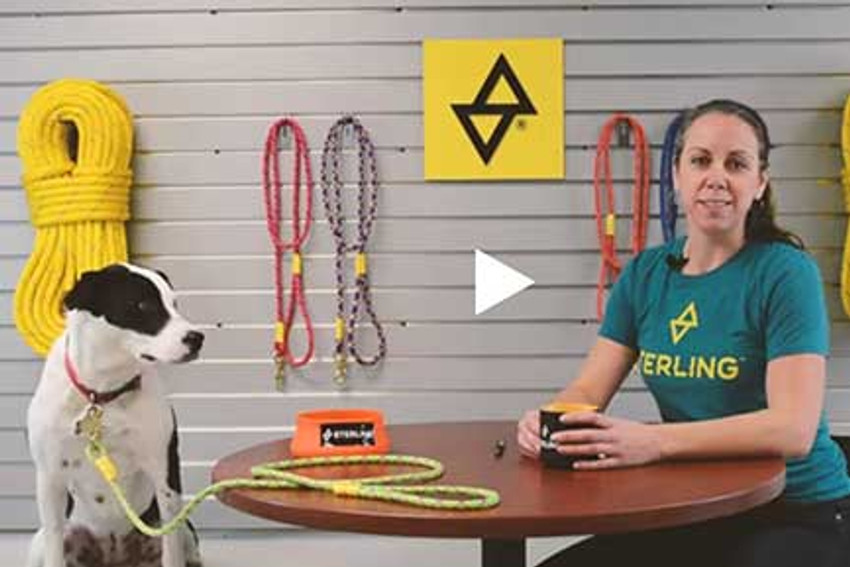

A Rope Engineer’s Guide: Which dynamic rope is right for you?

Sterling Solid Feb 20th 2026

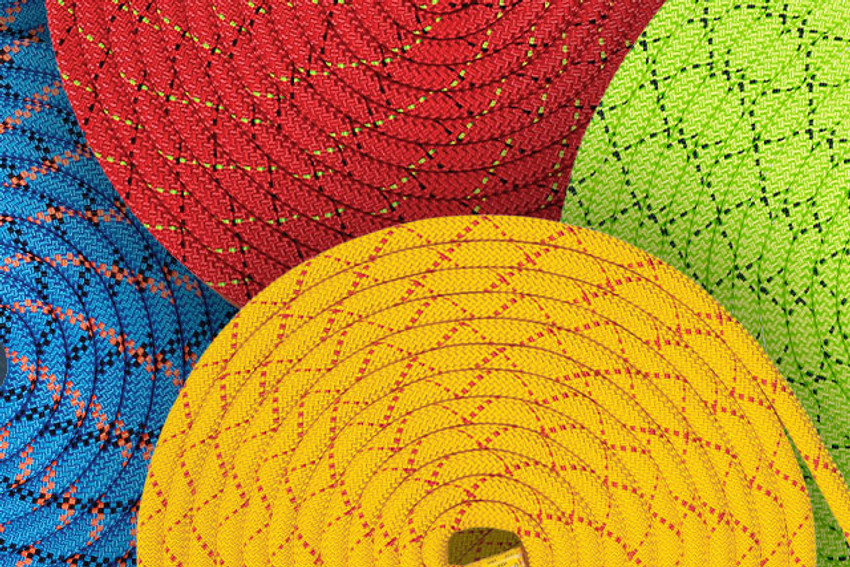

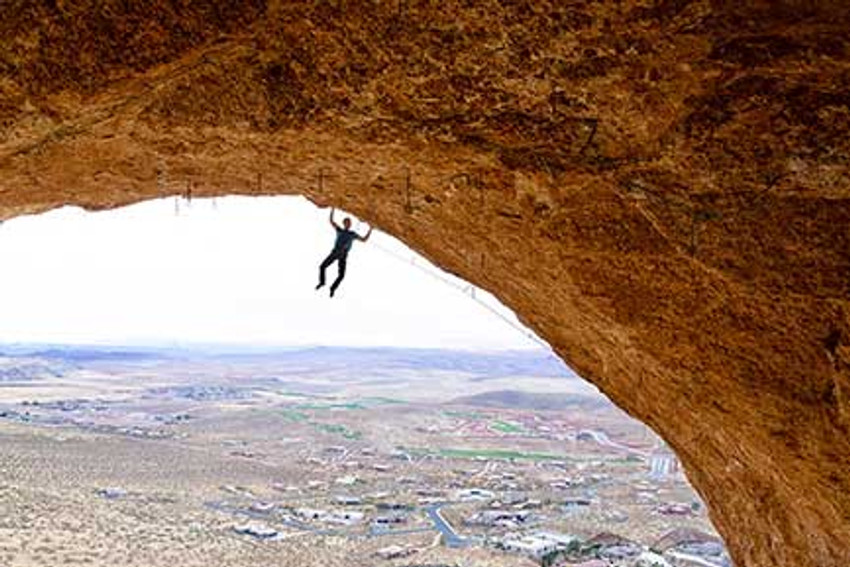

Choosing the Right Climbing Rope: 5 Key Factors Every Rock Climber Should Know Selecting the right climbing rope can feel overwhelming—especially with so many lengths, diameters, treatments, and constructions to choose from.

… read more

about A Rope Engineer’s Guide: Which dynamic rope is right for you?